Rob and the team at Screw Pile Solutions has been extensively trained by their Australian manufacturer, with a proven track record of 40 years combined experience in both the domestic and commercial piling and construction industries.

Screw piles offer a less intrusive and more time-effective alternative to traditional piles, and can be removed as quickly as they are installed.

Screw piles are the perfect solution for building foundations, ecologically sensitive sites, temporary structures, underpinning, furniture footings, and more. Chat to one of the friendly team today to find out how we can save you time and money on your next project.

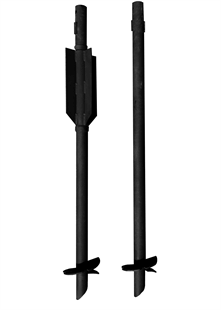

Our helix is designed to achieve incredible uplift integrity, as well as loading strengths. We can also use large lateral fins at ground level to achieve 4-way lateral resistance.

The helix of the pile is designed with a true through-cut on a single flight, with a 350 Grade Plate. The pipe used is 350 Grade with a Yield Stress of 570Mpa / tensile strength of 600Mpa. The piles can also be galvanised.

Our ground anchors are a unique four fin with a fully floating fin assembly which engages and mobilises a mass of soil around the top of the ground anchor pile, providing significant lateral support.

With our piles, we can also carry out horizontal drilling to achieve resistance, e.g. with retaining wall strengthening situations.

If concrete is used at all, it is only used to stabilise the top section of the pile, whether it be in a shallow strip footing or an individual pile cap.

Piles can be installed in the existing ground contour or a pre-excavated platform. When the piles are installed, there will not be any additional spoil removal required from the pile locations.

Due to the minimal disturbance of the pile install, this makes screw piles great for sensitive environments such as native vegetation settings, estuaries, and steep embankments.

Work can be carried out in any conditions providing the access for the machinery is safe. We do not require slurry clean out, submersible

pumps, or extra disposal costs due to adverse weather conditions.

Once marked out, installation of the piles requires the operator and his dogman on-site. When the machinery is set up, the piles are installed. There is no waiting for longer or shorter poles to achieve the required set, no spoil to remove, and no pole length wastage.

In a relative cost analysis, one of the greatest factors is the impact of time & manpower, including concrete scheduling, the cost of the concrete itself, pumps, and any associated downtime.

To give you an idea, the piles for a typical house can be installed in one day. This is great for managing projects and meeting tight

deadlines.

Once the driving helix is installed, the pile is lengthened with one or two meter extensions - there is no limit to the depth. As the

loading of the pile is measured as it is installed, we add on extensions until we achieve the required loading stated by the engineer. This depth may vary from pile to pile, but it insures we do not go any deeper than required.

In rare cases, where rocks or larger tree roots are present, it may affect the depth or pile locations. If this occurs, we will discuss with

the engineer the options for moving forward.

Each individual pile is drilled down to a specific Kn which is calculated from your engineers required loading. As each piles Kn is known at

all stages of drilling, we drill to a depth which is determined by the loading requirements. These depths are all dependent on the ground condition in that precise location.

We take accurate readings for each pier, not just random tested areas on the site. We measure the PSI of each pile as it is installed. This

is recorded & dispatched to the engineer for immediate PS3 certification. This is one of the advantages of using Screw Pile Solutions, as we have struck sites where, within metres, a differential reading is recorded.

As this is an engineered solution, engineers or building inspectors aren't required on site.

We can test your site prior to commencing work to establish the ground conditions and an approximate pile depth.

Think out of the box with Screw Pile Solutions. Versatile, effective, alternative to traditional foundations. No matter how big or small your project, we have a screw pile solution for you.

© 2020 Screwpile Solution Ltd • Website design by Fuel